Engineering fabrication has changed how products are produced. So, you can order a custom part and have it created at the touch of a button. Modern factories combine technologies, streamlining the production process and cutting costs.

Engineering Fabrication

Check out their machines if you’ve been looking for somewhere to do fabrications. Sometimes, it makes more sense to work with a well-equipped supplier. Since they have better capabilities, you can get everything done simultaneously.

CNC Machining

CNC machines use computers to control the machining process, making it incredibly precise. Plus, thanks to modern machine design, they work on multiple sides simultaneously. As a result of this change, it’s way more efficient than previously used techniques. So, it won’t cost you as much if you’re building something new, even if it’s a prototype.

Grinding and Finishing

After finishing the rough shape, you have to finish the product to make it perfect. Bead blasting has become a popular technique, owing to its utility. Another common technique would be grinding, which is similar to using sandpaper.

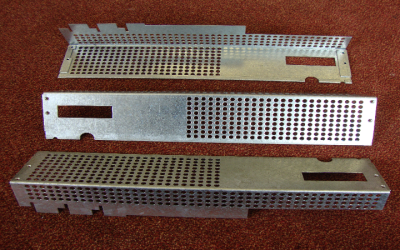

Milling and Drilling

Certain machines can make them fast if your product needs holes drilled into it. So, you don’t have to spend hours waiting for the holes to be made. Once the part has left the facility, it’ll have everything needed to meet expectations.

SAMS Fabrications Ltd operates a precision machine shop in Norfolk NR. Visit them at their website at

http://www.samsfabrications.co.uk/

to learn more.