No one can afford to waste time or money on delays in the delivery of vital goods and services. This particularly holds true with any enterprise dependent on high-quality metal fabrication and finishing work. As a result, industrial clients subcontract with professional service companies specializing in metal fabrication. This ensures the quick and efficient completion of vital sub-assemblies needed to complete their own production work.

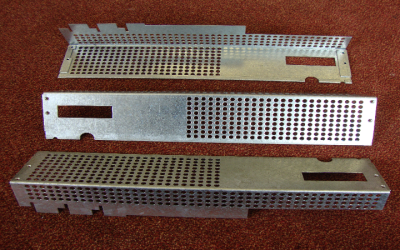

Machining shops regularly engaged with Metal Fabrications have on hand a complete array of the latest metalworking tools available, including everything from drill presses, lasers, and hydro-jets to large lathes, vertical milling machines, and welding equipment. Fabrication shops fashion completed metal parts and structures through precision cutting, sawing, bending, shearing, or chiseling to reshape plate steel or aluminum. Welding is then utilized for assembly and is performed by certified technicians with oxy-acetylene or plasma torches. All work follows outlines provided by contractor’s blueprints and complete sets of specifications. With this information, technicians have an exact guide as to what a client needs for a finished product. When the fabrication work is completed, final assembly and installation can proceed.

One advantage afforded through contracting with a large Fabrication shop is convenience. Everything a client requires can be found in the one location, dispensing with any need to seek different vendors to acquire materials or perform services. In addition to having the necessary equipment and personnel available, the facility also has on the premises a large supply of plate metal. These plates come in a wide range of sizes and thicknesses as well as types of metal to meet any specification. This streamlines the process involved in completing a project and enables the client to control all costs for materials acquisition in addition to those for the actual work.

SAMS Fabrications has served big clients since 1988. The company has handled projects for both small- and large-scale operations. The staff will help with all details involving the project and ensure that the work will be completed as specified, on schedule, and within budget. Contact them today.