Any metal’s machinability depends on the physical properties of the metal in addition to the cutting conditions at hand. Aluminum has greater machinability then many other metals due to the fact that it is easy to shape and chip.

As a highly flexible and adaptable metal, aluminum is useful for various industrial applications that involve tooling and welding. It is also perfect for prototyping due to its low cost and formability benefits. Exceptional precision is desirable when machining aluminum.

Applications Using Aluminum Alloys

Due to its excellent machinability characteristic, aluminum is ideal for use in a number of different applications and products, including camera parts, cell phones, gears, door knobs, and machine parts.

Formability and Machinability Characteristics of Aluminum Alloyes

The classes of aluminum alloys listed below offer varying formability and machinability capabilities.

7xxx

This class of aluminum alloys consists of combinations of zinc and copper or zinc and magnesium. These alloys provide significant strength which also makes them less than ideal to form.

6xxx

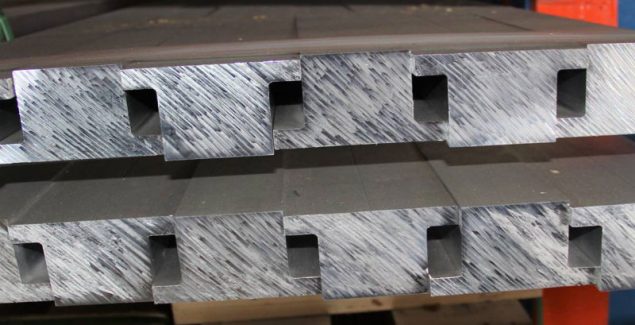

Magnesium and silicon are added to this series of aluminum alloys. These alloys respond to formability well but are vulnerable to cracking. They’re generally used for extrusions meant for architectural applications.

5xxx

Magnesium is added to these alloys. They offer good formability.

4xxx

Commonly utilized for the manufacture of welding wire, these alloys include the addition of silicon

3xxx

This series of aluminum alloys contain approximately 1% manganese. They are highly applicable for forming applications and also do not manifest any perceptible loss of ductility.

2xxx

Also called copper alloys, this series of aluminum alloy has excellent machinability characteristics, but minimal cold formability, except when it is annealed.

1xxx

As approximately 99% pure aluminum, this series of alloys possesses high ductility.

You can depend on a precision metal supplier with decades of experience in the industry to provide you with various aluminum custom extrusion and plate applications. The industry serves by such a supplier may include pneumatic, hydraulic, medical, machinery manufacturing, robotic automation, and aerospace.

If you are ready to benefit from the various types of aluminum alloys that can accommodate your machining requirements get in touch with a reliable aluminum supplier in the industry today.